Detail

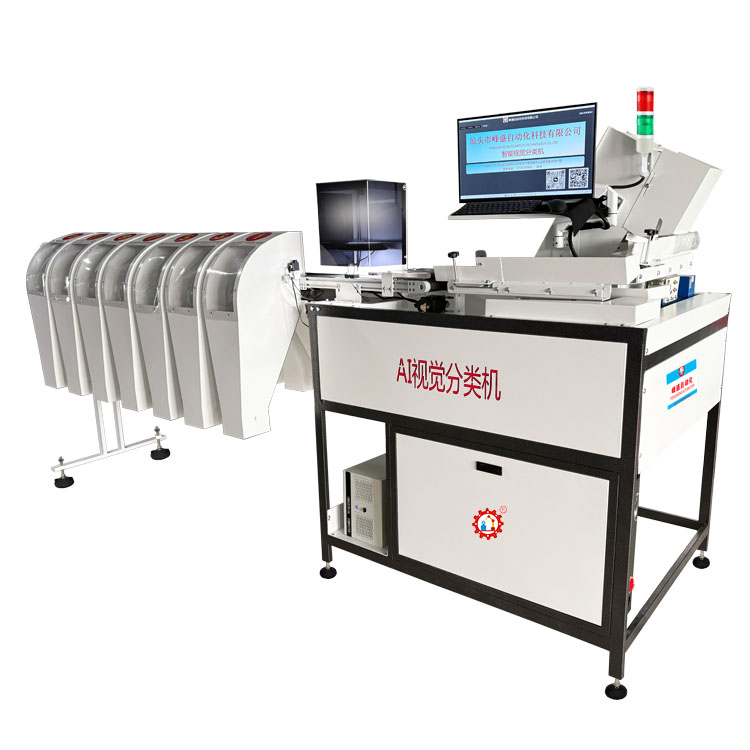

Intelligent visual sorter (FS-805A)

Main uses:

Visual sorter is mainly used to detect the defects and classification of product appearance; It can detect all kinds of appearance defects in all parts of the workpiece in all directions. The detection speed has reached the domestic leading level, and the fastest image detection speed can reach 1800 times/minute, which is equivalent to 4 to 8 skilled manual visual inspection personnel working at the same time; It can be applied to all kinds of building blocks, metal processing parts, electronic components, hardware, fasteners and other industries.

Functional features:

1. High detection efficiency: the front and back detection of the workpiece can be completed without turning over.

2. A variety of feeding methods: A variety of feeding methods can be quickly switched between different models, and one device can meet the detection of multiple types of workpieces, thus solving the problem that one device can only detect one type of workpieces in similar products.

3. Independent research and development of testing software: it can be customized according to customers' products and requirements to meet customers' various testing and sorting needs.

Product information:

1. This new product has the most stable and advanced AI analysis algorithm system in domestic structural design at present. Fully automatic PLC control program imported from Taiwan Province is combined with high-pixel camera lens, high-quality computer integrated machine is adopted, and intelligent AI software algorithm is independently developed, which makes the whole equipment super stable, easy to control, high precision and high efficiency. This new product breaks through the sorting problem of small, miscellaneous and chaotic materials.

2. This product can detect the appearance size of products from multiple angles, and carry out multi-angle and efficient visual sorting on a variety of mixed products.

This product has the advantages of simple acquisition and short training time (taking 15 stations as an example, the longest acquisition time is about 2 hours).

3. Solve the problem that the factory is identified and classified by naked eyes, thus reducing the labor-intensive, inefficient, tedious and tiring work in the factory, improving the advantages of less labor, small land occupation, high accuracy, high efficiency and low cost, and allowing customers to easily open up a larger market.

Special reminder:

All models of the company are standard models, and can also be customized according to customer requirements. Please know before placing an order and get in touch with us. We will reply as soon as possible. Thank you!

Optical sorting machines

- Item No.:FS-805A

- Product size:350*120*180 cm